Understanding Concrete Coring and Drilling: A Comprehensive Guide

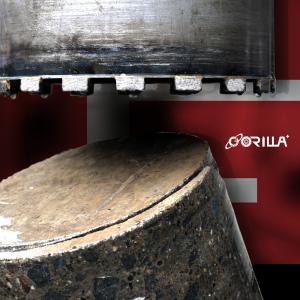

Concrete drilling, also known as coring, is an essential technique used in various construction and renovation projects. This cylindrical drill is specifically designed to create precise holes through different surfaces, including concrete, wood, rocks, and even ice. The core drill consists of a motor, handle, and drill bits, with the drill tips typically coated in either diamond or carbide to enhance performance.

What is a Core Drill?

The primary distinction between a core drill and other cement-cutting tools lies in its ability to extract a cylindrical sample from the material. The hollow center of the drill enables it to carve out a core sample, which retains the shape of the drill's walls. This is particularly useful for testing the integrity and composition of concrete and other materials.

Core drills come in various sizes and power levels, tailored to specific applications. While a small core drill might suffice for home use, medium-sized drills are suitable for buildings and mining operations, whereas large drills are essential for extensive concrete cutting on major construction projects.

Benefits of Concrete Drilling

Drilling holes in concrete offers numerous advantages, such as:

- Easy Installation: Enables the installation of shelves, lighting fixtures, and more.

- Time Efficiency: Proper tool selection and usage streamline the drilling process, saving significant time.

- Safety: When used correctly, concrete drilling minimizes risks associated with manual installation methods.

Types of Concrete Drilling

Concrete drilling can be categorized into two main types: hard coring and soft coring, each suited for different geological conditions.

-

Soft Coring

- Application: Ideal for taking core samples from unconsolidated materials, commonly used in environmental projects.

- Depth: Typically reaches depths of around 500 feet, although deeper samples are possible.

- Method: Utilizes a punch core system with two nested barrels. The inner barrel captures the core sample, while the outer barrel provides casing to prevent the hole from collapsing. This technique protects the sample's integrity from air or fluid exposure.

-

Hard Coring

- Application: Designed for materials as hard or harder than sandstone, such as competent rock.

- Depth: Capable of reaching depths up to 5,000 feet or more.

- Method: Also uses two nested barrels, but the outer barrel is extended first. This allows the core sample to be washed with drilling fluid or air without risking disturbance or contamination. Hard coring is often referred to as diamond coring due to the use of drill bits embedded with small diamonds for cutting through tough materials.

Conclusion

Understanding the different types of concrete drilling and their applications is crucial for anyone involved in construction or renovation projects. With the right tools and techniques, concrete coring can be executed efficiently, ensuring high-quality results and structural integrity. Whether you are a professional contractor or a DIY enthusiast, mastering the art of concrete drilling will significantly enhance your project capabilities.