Concrete Drilling Machine Usage and Troubleshooting Guide

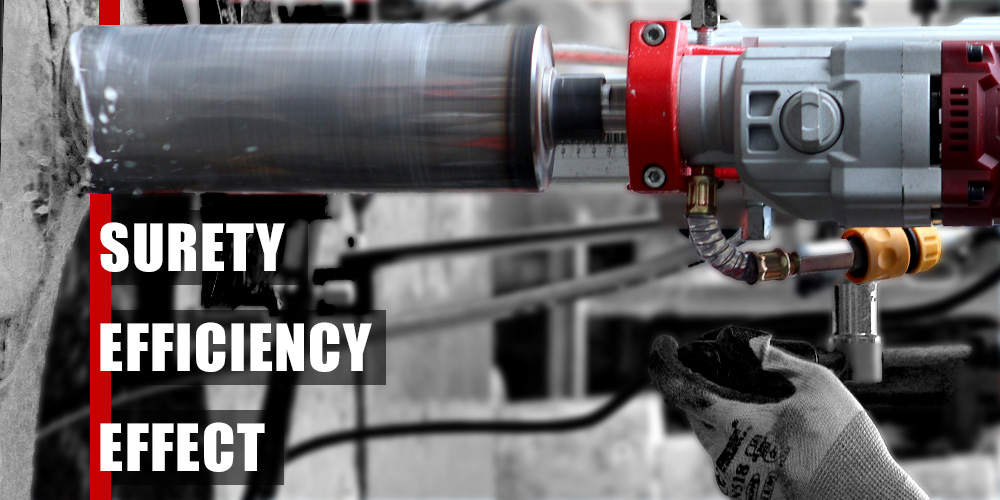

In concrete construction, the concrete drilling machine is an indispensable tool. It makes it easy to drill holes in walls, floors, and other surfaces, helping us accomplish various tasks. However, it's important to be aware of the potential dangers associated with using diamond drill bits, especially for novice users who may encounter injuries while drilling.

Usage Tips

Here are some key points to keep in mind when using a concrete drilling machine:

- Equipment Inspection: Before starting work, ensure that all components of the drilling machine (such as diamond core bits) are in good condition. Check the power supply and cables for any signs of wear or damage.

- Safety Gear: Always wear appropriate safety equipment, including goggles, gloves, and ear protection, to shield yourself from debris and noise.

- Use of Cooling Water: Adding water during the drilling process can effectively cool the drill bit, reducing temperature and wear. Additionally, using water helps to clear away dust generated from drilling, keeping the work area clean.

- Stability and Support: While handheld drills are convenient, ensure the equipment remains stable during drilling. Use supports or brackets if necessary, especially when drilling larger or deeper holes.

- Operating Techniques: Beginners should maintain steady hand movements while drilling and avoid applying excessive pressure. Gradually increase the pressure to allow the drill bit to penetrate the material effectively.

- Regular Breaks: Long periods of operation can lead to fatigue, impacting safety and efficiency. Take regular breaks to ensure you remain in optimal condition.

Common Issues and Troubleshooting

-

Water Seal Leakage

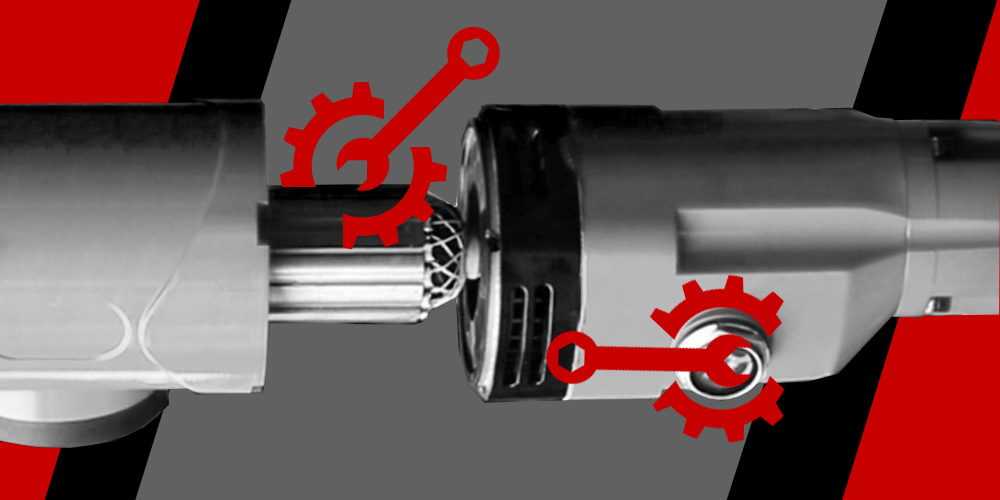

- Internal Leakage: Typically manifests as water leaking from the fan and gearbox. This can allow cooling water to enter the gearbox, diluting lubricating oil and increasing wear. Check the seals for integrity and replace if damaged.

- External Leakage: If water leaks from the shaft seal, you can resolve this by removing the seal cover screws and replacing the water seal. Additionally, verify that the seal is installed correctly.

-

Motor Suddenly Stops Working

- First, check if the power supply is functioning. If not, disconnect the power and inspect the carbon brushes for wear or damage. If issues are found, replace the carbon brushes. Also, check if the internal connections of the motor are loose.

-

Sparking or Frequent Carbon Brush Damage

- This issue can arise from damaged rotor bearings or excessive overloading of the machine. If the motor overheats, it may indicate an overload of current. It is advisable to contact a professional technician for inspection and repairs.

-

Drill Bit Getting Stuck or Reduced Cutting Efficiency

- A stuck drill bit may be due to excessive pressure or an unsuitable drill bit for the material. Check if the drill bit is worn and replace it if necessary. Also, ensure there is sufficient cooling water during drilling.

-

Excessive Vibration

- Vibration may be caused by an unbalanced drill bit or improper equipment stabilization. Ensure the drill base is securely fixed and check that the drill bit is properly installed.

-

Abnormal Noise

- If the motor emits unusual noises, it may indicate wear in internal components or insufficient lubrication. Stop using the machine immediately and check if the lubricant needs replacing.

We hope this guide helps you in your concrete drilling tasks, ensuring that each operation is safe, smooth, and efficient! If you have any questions, feel free to reach out.