In-Depth Analysis of Dry Diamond Core Bits: A High-Efficiency Tool in Construction

Dry diamond core bits are high-performance tools specifically designed for drilling into hard materials such as concrete, brick, and stone. Unlike wet core bits, dry bits operate without the need for water or coolant, providing exceptional flexibility on job sites, especially in environments where water access is limited or quick repositioning is required. Here’s a closer look at the advantages and specialized features of dry diamond core bits:

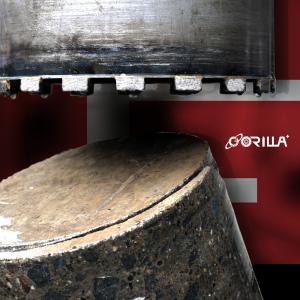

- Diamond-Impregnated Segments: The Key to Cutting Efficiency and Durability

The cutting edge of dry diamond core bits is crafted with diamond-impregnated segments, which distribute diamond particles evenly across the blade edge. Given diamond’s high hardness and wear resistance, these segments enable the bit to penetrate tough materials with ease while extending tool lifespan. The diamond segments create a sharp cutting surface, reducing resistance and friction during drilling, and thus improving both speed and precision.

- Special Heat Dissipation Design: Effective Temperature Control

Managing high temperatures during drilling is one of the main challenges with dry drilling. Dry diamond core bits feature advanced heat dissipation designs, such as heat vents and cooling grooves, which help reduce temperature build-up and prevent material damage or bit degradation. This design protects the bit’s cutting performance and enhances the safety and stability of the drilling process.

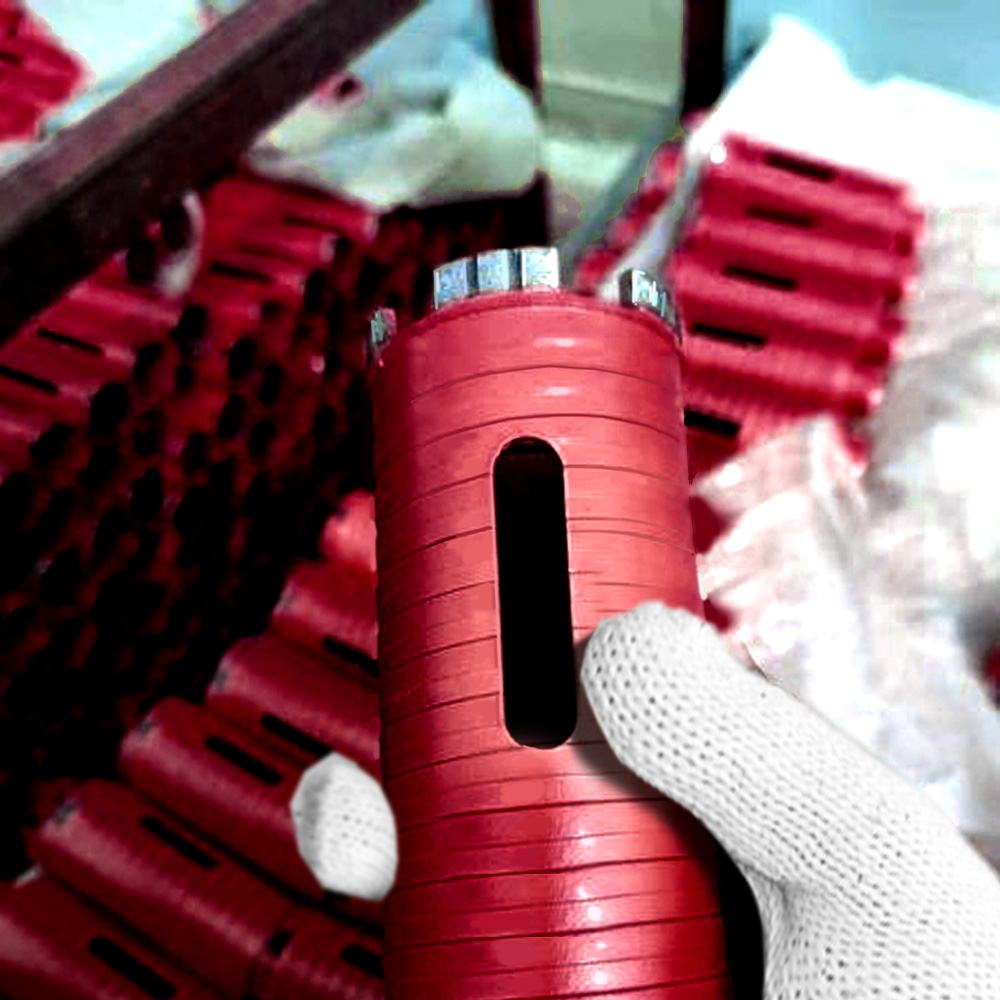

- Multi-Layer Diamond Structure: Longevity and Consistent Performance

Premium dry diamond core bits often incorporate a multi-layer diamond structure. When the outer layer of diamonds wears down, inner layers gradually become exposed, allowing the bit to maintain optimal performance over a longer period. This structure provides consistent cutting power and drilling speed, ultimately enhancing drilling efficiency and reducing labor time and costs.

- Portability and Adaptability in Non-Water Environments

Since dry core bits don’t rely on a water cooling system, they are ideal for job sites where water supply is limited or unavailable, such as high-rise buildings, interior spaces, and areas where water connections are hard to access. This portability allows for greater flexibility in operation, especially in plumbing, electrical wiring, and ventilation installations, significantly increasing both productivity and convenience for contractors.

- Versatile Applications: A Flexible Tool for Projects of All Sizes

Dry diamond core bits are highly adaptable across a wide range of construction and installation projects. With different diameters and depths available, they accommodate various hole sizes, allowing contractors to meet specific needs in pipework, electrical conduits, and ventilation system installations. This versatility minimizes the need for additional cutting and adjustments, improving overall project quality.

- Economic Efficiency: Cost Savings and Material Protection

Dry drilling not only enhances productivity but also reduces the need for on-site water handling, which lowers environmental impact and resource costs. The precision of dry core bits leads to less material waste and fewer edge breaks, helping construction teams reduce costs and improve the overall economic efficiency of their projects.

Dry diamond core bits combine robust construction and innovative heat dissipation features to offer construction professionals an efficient, durable, and adaptable solution for drilling. They play an essential role in modern construction and renovation projects, providing outstanding performance in a wide range of applications.